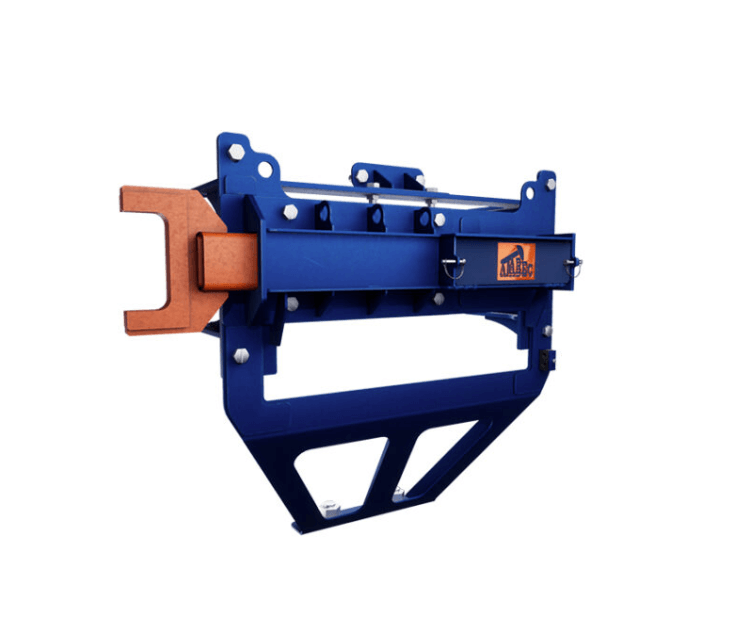

Atabec Safety Lock™

ENGINEERED FOR YOUR BEAM PUMPING UNITS

The Atabec Safety Lock™ is custom fit and scaled to fit your pumping unit. The mounting bracket is paired with our common locking assembly to provide an engineered solution to optimize safety at the well site.

Engineered for all sizes of pumping units, the Atabec Safety Lock™ employs a minimum 3:1 safety factor. A simple yet robust design, you can rely on the strength and durability of Atabec to increase productivity, save dollars as well as reduce traffic and unnecessary injuries at the well site.

The Atabec Safety Lock™’s patented technology is designed to improve worker safety, decrease costs, and reduce the environmental impact of operations.

It minimizes down time and optimizes operational maintenance, all while maximizing safety goals. Counterweights on most beam pumping units can weigh up to 10 tons. That weight, combined with momentum and pinch points, creates extreme danger to employees. Statistics indicate that every year one service employee in the U.S. is killed, and dozens more are injured worldwide while conducting beam pumping units maintenance. Do not put your employees at risk – trust the engineered strength of Atabec Safety Lock™.

Atabec’s simple-to-operate hand pump hydraulic lock engages and disengages from outside the danger area. With the hydraulic fork engaged, there is zero crank movement – even with no brake and full power applied to the unit. One hundred percent non-toxic and environmentally friendly fluid is utilized in its closed loop system.

HOW ATABEC WORKS TO IMPROVE WORKER SAFETY

- Isolates & prevents movement of crank arms

- Eliminates need for personnel to enter the swing area to properly lock out the beam pumping units

- Safety lock actuated from outside of weight guards

- No crank movement with beam pumping units safety lock engaged

- Horse’s head can be installed with weights at any position

- The Atabec Safety Lock has a 3:1 safety factor

- Eliminates chain & boomer on sheave or chain on brake

- Safety lock released from outside the danger zone

- Client & personnel confidence that threat of danger is eliminated

- Eliminates usage of the brake pawl which is subject to wear damage

- Eliminates damage when over-centered from applied force

HOW ATABEC CREATES COST SAVINGS

- Permanently mounted on the beam pumping unit easily and quickly

- Allows beam pumping units to be locked at 12:00 o’clock position for service rig work

- Allows beam pumping units to be locked at 6:00 o’clock position for inspection & general maintenance

- Allows beam pumping units to be locked at 3:00 & 9:00 o’clock position for adjusting counterweights

- Allows beam pumping units to be locked at 4:30 o’clock position for adjusting stroke length

- Reduces time required to secure beam pumping units – no longer requiring locking breakers

- Eliminates requirement of cranes or pickers

- Eliminates potential of cracked sheaves on belt pulley

- Service providers can be trained to engage lock expediting workflow